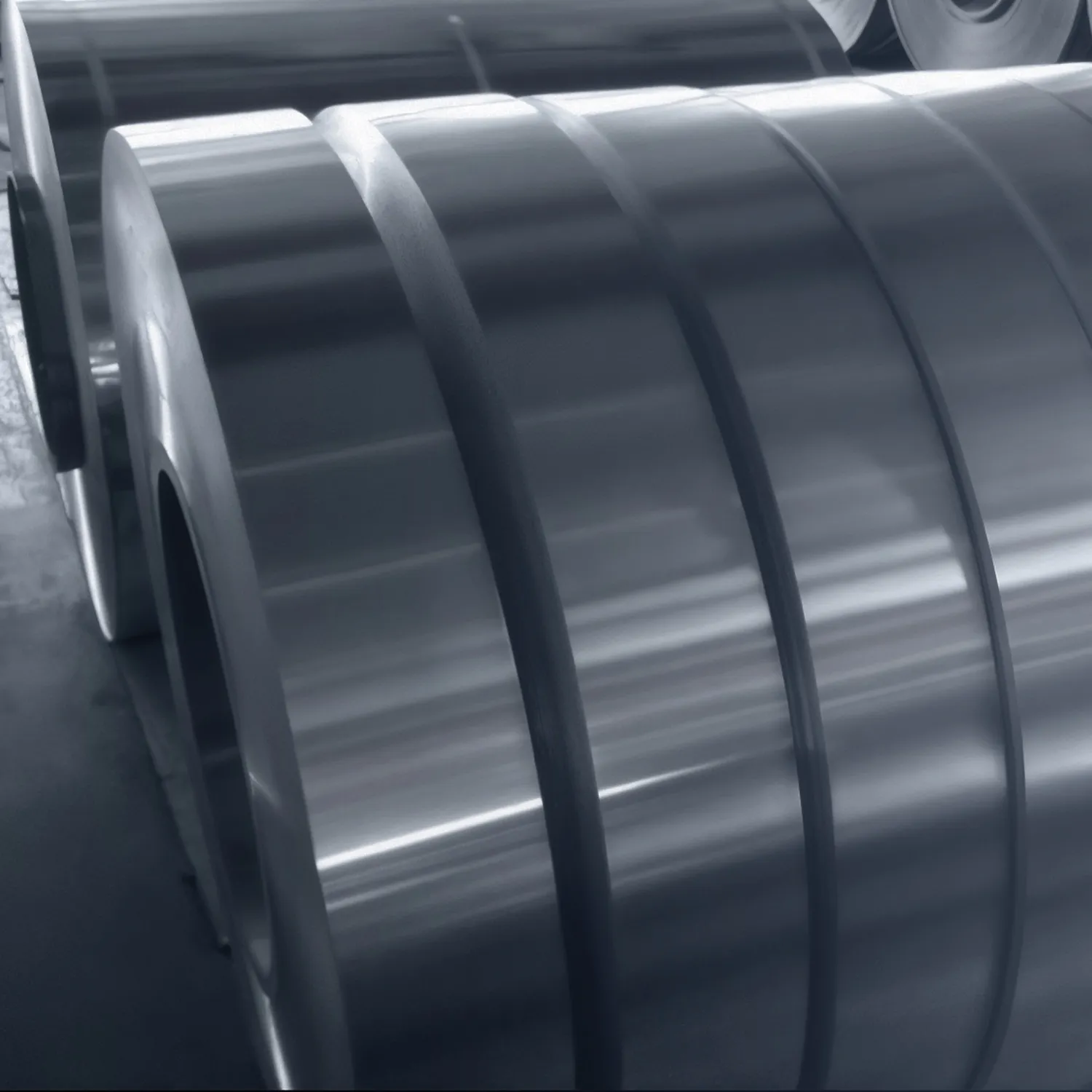

Aluminum Cast Coil (Cast Roll)

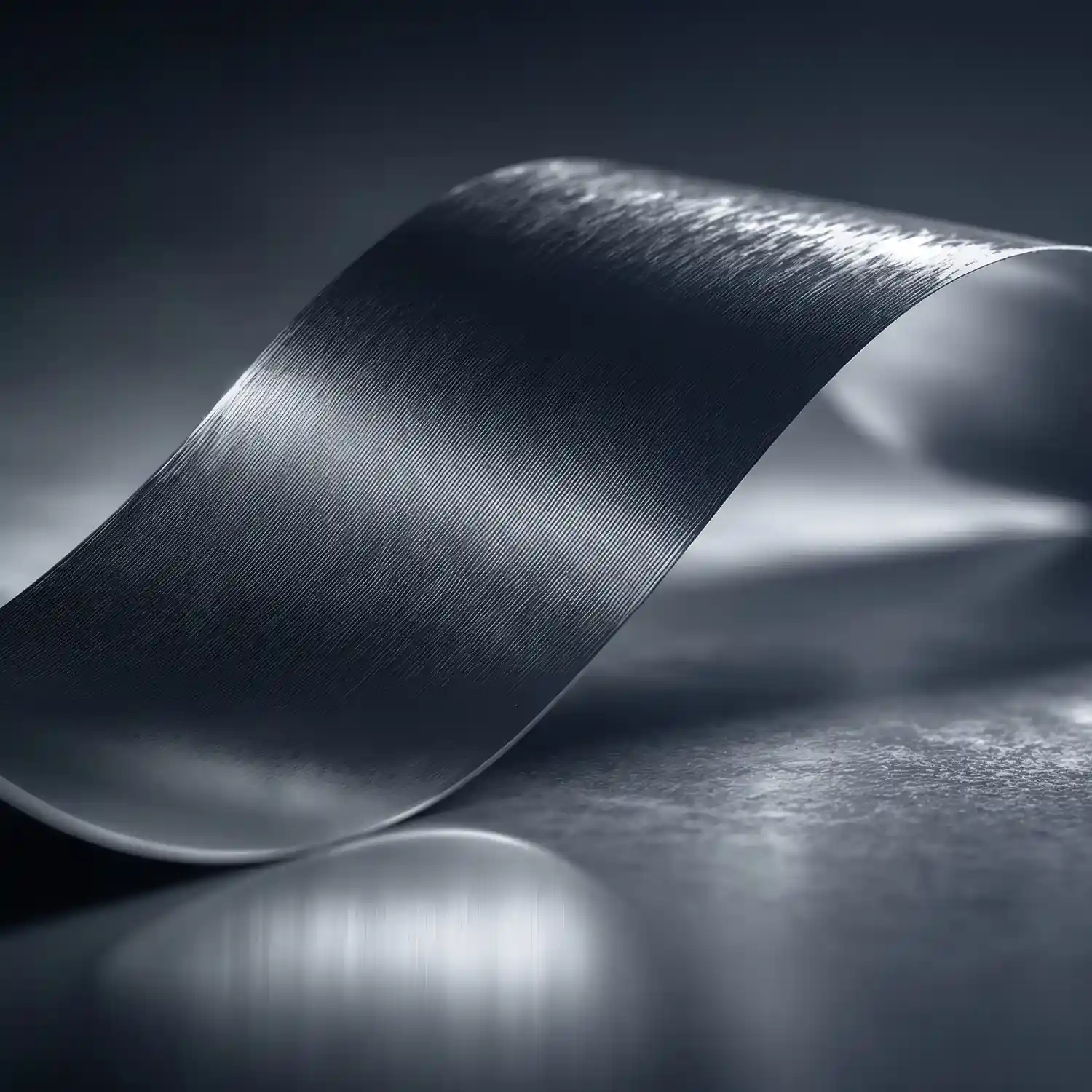

Aluminum cast coils produced with continuous casting technology constitute the primary product of our flat-rolled production, offering wide dimensional ranges and high surface quality.

Product Description

Aluminum Cast Coils are semi-finished aluminum products manufactured in cast-roll form through a continuous casting line. Serving as the initial step in the production of aluminum flat-rolled products, this product range provides the basis for subsequent processes such as cold rolling, sheet, and strip production.

Our products are manufactured in a thickness range of 4–10 mm and a width range of 800–1650 mm. With an annual line capacity of 30,000 tons, we are able to meet high-volume demands.

Production Technology & Alloy Series

Our cast coils are produced using continuous casting technology, ensuring a homogeneous internal structure, stable mechanical properties, and superior surface quality. Within our aluminum flat-rolled product range, AA 1XXX and AA 3XXX alloys are the primary options, while 1200 and 8000 series alloys can also be provided upon request.

Key Dimensional Ranges

- Thickness range (casting line): 4–10 mm

- Width range (casting line): 800–1650 mm

- Annual casting line capacity: 30,000 tons

- Technology: Continuous Casting

Technical Specifications – Cast Coil

| Product Type | Thickness (mm) | Width (mm) | Inner Diameter (mm) | Outer Diameter (mm) |

|---|---|---|---|---|

| Cast Coil | 4.00 – 8.00 | 800 – 1650 | 508 | 1800 |

Application Areas

Aluminum cast coils are used as the initial input in the flat-rolled production chain and support a wide range of industrial applications. As a primary feedstock for cold-rolled coil, sheet, and narrow strip production, they serve as the basis for applications in the following industries:

- Automotive and transportation

- Construction and façade cladding

- White goods and household appliances

- Electrical–electronic and conductor applications

- Packaging and printing industries

- Solar energy and industrial machinery components

Production & Quality Advantages

- High efficiency and stable quality ensured by continuous casting technology

- Homogeneous internal structure and excellent surface finish

- Flexible use with a wide thickness and width range

- Wide alloy selection including AA 1XXX and AA 3XXX series

- Ideal starting material for cold rolling, sheet, and strip production